Est. 1953

Tradition in Truck Repair

Generational Hi-Rail Mastery: Five Successive Eras of Excellence for Your Fleet Advancement

At Schroeder Truck Repair, we take pride in providing high-quality services to our valued customers.

As a family-owned union shop, we hold strong to our traditions while offering top-notch truck repair services. With over seven decades of experience, our small, independent truck repair shop has a longstanding commitment to excellence, making us the ideal choice for all your fleet service and truck repair needs.

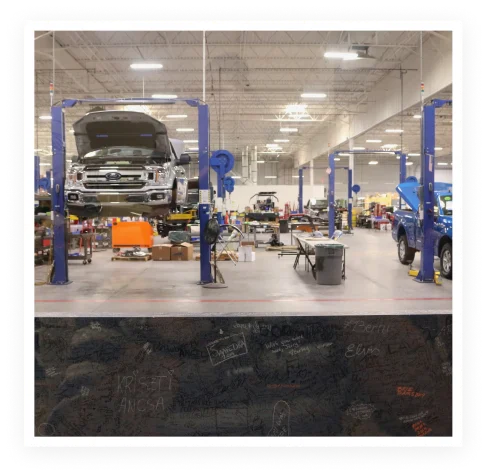

Fleet Services

Quality Solutions for Fleet Management Personnel and Fleet Services

We understand the importance of keeping your fleet on the road and minimizing downtime. Schroeder Truck Repair specializes in providing comprehensive fleet services with a focus on short lead times and high-quality workmanship to get your trucks back in operation promptly.

Whether you’re a fleet manager who needs an emergency repair for a single fleet vehicle or preventive maintenance for your entire fleet, Schroeder is here to deliver excellent service with efficiency.

01

Fleet Maintenance

Our fleet maintenance services are tailored to keep your vehicles in peak condition. We offer regular maintenance services such as oil changes and fluid checks, as well as scheduled preventative maintenance that includes fuel filter replacements, air filter checks, greasing, and ensuring DOT compliance. We address all safety issues and offer a tiered preventive maintenance system based on vehicle mileage and your specific needs.

02

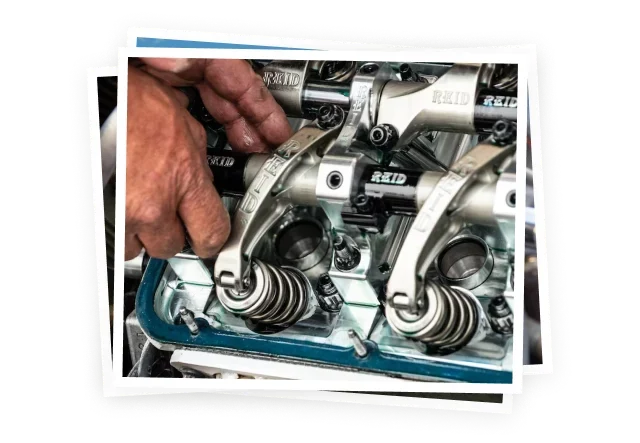

Fleet Repair

When your trucks require repair, our experienced team can handle it all. From engine troubleshooting and diagnostics to complex emergency repairs, we utilize the latest software to pull codes, examine wiring diagrams, troubleshoot issues, and implement fixes based on our decades of industry expertise. Our skillset covers engine and electrical diagnostics, as well as brake, clutch, hydraulic, and transmission replacements and diagnostics.

03

Fleet Equipment Installation

Our installation process encompasses the installation of customer equipment as well as providing guidance about suitable equipment based on your specific requirements. Whether you need headache racks, crane installations, PTO installations, pump installations, clutch, transmission, engine, or camera installations, Schroeder's got you covered. We can also perform modifications and re-installations of new components and add-ons.

01

01

Power Take Off Installation

We specialize in Power Take Off (PTO) installations for various applications, including truck bed movement, wood chippers, water truck pumps, public works vehicles, and more. Our skilled technicians are well-versed in PTO systems to ensure your equipment functions smoothly.

02

02

Hi Rail Truck Services

Schroeder Truck Repair offers comprehensive Hi-Rail truck services, including re-installation of hi-rail parts and new hi-rail system installations. We provide preventive maintenance, ongoing upkeep, and inspections to ensure your Hi-Rail equipment remains compliant with Federal Railroad Association (FRA) regulations.

03

03

Crane Services

Our crane services cover installation, maintenance, and repairs, including hydraulic work. We work with a range of crane brands and models, with expertise in Hiab and Palfinger, to ensure your cranes operate at their best. We work with expertise and efficiency, keeping your costs as low as possible and your cranes operational.

04

04

Pony Motor Services

In addition to truck repairs, we offer pony motor services, including oil changes, filter replacements, and fuel system maintenance. We can work on a variety of small pony motors, generators, forklifts, and other equipment to meet all your needs.

Why and When to Schedule Fleet Services and Preventive Maintenance

Fleet preventive maintenance is an essential aspect of keeping your commercial vehicles in optimal working condition while ensuring driver safety and the longevity of your assets.

Preventive maintenance involves a series of planned, routine checks and services aimed at identifying and addressing potential issues before they escalate into costly breakdowns. There are several reasons why scheduling fleet preventative maintenance is crucial for any fleet management operation.

01

First and foremost, preventive maintenance helps to prevent unexpected and costly breakdowns. Regularly scheduled inspections and servicing can identify wear and tear on critical components, allowing for timely repairs or replacements. This proactive approach not only minimizes downtime but also keeps repair costs predictable and manageable. Additionally, well-maintained vehicles tend to be more fuel-efficient, which can lead to significant cost savings over time. This can be especially beneficial when fuel expenses represent a substantial portion of your fleet operations budget.

02

Another key benefit of preventive maintenance is enhanced safety. Well-maintained vehicles are less likely to experience sudden failures that can lead to accidents. Keeping your fleet in top shape ensures that your drivers are less likely to encounter unexpected issues on the road, reducing the risk of accidents and associated liabilities. Moreover, adhering to a preventive maintenance schedule can also help your fleet stay compliant with DOT safety regulations, further mitigating risks.

So, when should you schedule fleet services and preventive maintenance?

Ideally, preventive maintenance should be scheduled at regular intervals and in alignment with manufacturer recommendations. Factors such as vehicle type, usage, and environmental conditions can influence the specific maintenance schedule. Typically, preventive maintenance intervals are based on mileage, engine hours, or time intervals, whichever comes first. For instance, oil changes, brake inspections, and filter replacements should be conducted at the recommended intervals.

A well-structured preventive maintenance program ensures that these critical tasks are never overlooked, promoting the safety and reliability of your fleet. The Schroeder team can help you identify the best preventative maintenance plan and schedule for you fleet program. Ultimately, by proactively maintaining your vehicles, you reduce the likelihood of unexpected breakdowns, minimize repair costs, improve safety, and extend the lifespan of your fleet, making it a sound investment in the long run.